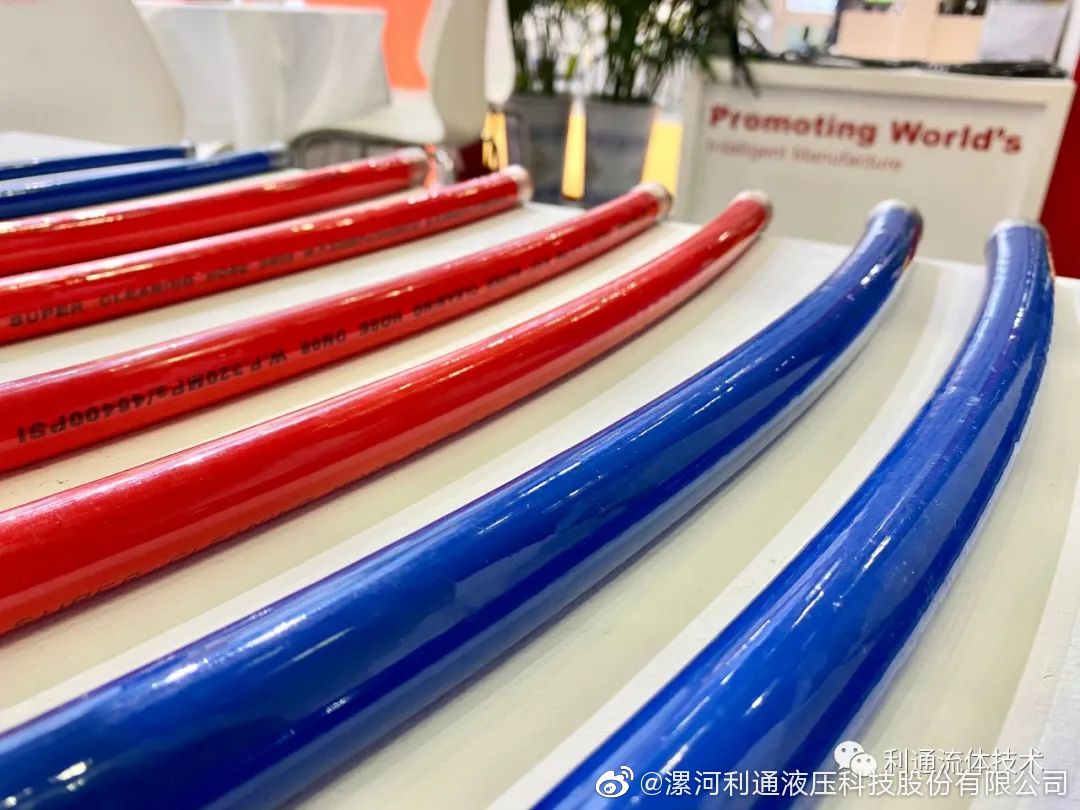

Ultra high pressure resin hoses

Ultra high pressure resin hoses, as a high-performance flexible pipeline, play a crucial role in modern industrial fields. It uses a plastic material extruded into a flexible hose as the inner core, which is reinforced with high-strength industrial fibers or steel wires through weaving or winding. It can withstand extremely high working pressure and has various excellent performance characteristics, making it an indispensable key component in many industries.

The structure design of ultra-high pressure resin hoses is exquisite, usually divided into three layers: inner hose layer, skeleton reinforcement layer, and outer adhesive layer. The inner hose layer is generally made of wear-resistant and high tensile synthetic rubber or special synthetic resins, such as nitrile rubber (NBR) or polyurethane fluorine (PU), which provide good heat resistance and chemical stability for the hose and can effectively resist the erosion of various fluid media. The skeleton reinforcement layer is woven from high-strength industrial fibers or steel wires, which greatly improves the pressure bearing capacity and wear resistance of the hose, enabling it to be used for a long time under high pressure, high temperature, and harsh environments without deformation or rupture. The outer adhesive layer is made of weather resistant materials, such as high-quality polyurethane elastomers, to protect the hose from external environmental damage and further extend its service life.

Ultra high pressure resin hoses have many significant performance advantages. Firstly, it has high compressive strength and can withstand working pressures of up to several hundred megapascals, meeting the needs of various high-pressure hydraulic systems. At the same time, it has minimal deformation under pressure and can maintain stable shape even under extreme pressure, ensuring smooth fluid transmission. Secondly, ultra-high pressure resin hoses have good resistance to media, excellent aging resistance, and can resist the erosion of various chemical substances for a long time, maintaining the purity of the fluid and stable operation of the system. In addition, the inner wall of the hose is smooth, the liquid resistance is low, the hydraulic loss is small, and the power transmission efficiency is high. The outer surface is made of wear-resistant materials, which have much higher wear resistance than traditional rubber pipes and are known as the king of wear resistance.

Good flame retardancy and impact resistance are also important characteristics of ultra-high pressure resin hoses. In various applications of hydraulic oil transportation, it has demonstrated irreplaceable superiority. Hose materials have a wide range of working temperatures, from embrittlement at low temperatures to thermal stability at high temperatures, all of which can maintain excellent performance and adapt to changing working environments. In addition, ultra-high pressure resin hoses have good flexibility and can be easily used in complex pipeline layouts without installation difficulties due to high hardness. This flexibility also makes the hose more elastic and earthquake resistant during operation, effectively improving the stability of the system.

In industrial production, the application range of ultra-high pressure resin hoses is extremely wide. In the field of construction machinery, as a key component of hydraulic systems, it can withstand enormous internal and external pressures, ensuring efficient operation and precise control of equipment. The working state of oil drilling equipment is extremely complex, often requiring continuous operation in harsh environments such as high pressure, high temperature, and heavy pollution. Ultra high pressure resin hoses, with their excellent pressure bearing capacity and chemical stability, can effectively solve the problems in hydraulic oil transportation, improve the overall stability and work efficiency of drilling equipment. In the aerospace field, there is a high demand for lightweight, high-strength, and high reliability materials. Ultra high pressure resin hoses have become indispensable connecting components due to their excellent performance. In addition, it is widely used in various industries such as chemical, coal mining, shipbuilding, automotive, medical equipment, etc., becoming an ideal hydraulic and pneumatic hose for various mechanical equipment.

The application of ultra-high pressure resin hoses in specific industries highlights their unique value. For example, in oil extraction, it is a key link between the wellhead and storage tanks, pump stations and transmission pipelines, ensuring the safe and efficient transmission of high-pressure, high flow petroleum based hydraulic oil. In the field of mechanical manufacturing, the hydraulic system of heavy machinery equipment, such as excavators, cranes, injection molding machines, etc., cannot do without the support of ultra-high pressure resin hoses. These devices require frequent changes in construction positions and operating conditions during the working process, which places high demands on the flexibility and adaptability of the hydraulic system. Ultra high pressure resin hoses are an ideal choice for these hydraulic systems due to their wear resistance and high pressure resistance.

With the advancement of Industry 4.0 and intelligent manufacturing, the ultra-high pressure resin hose industry is developing towards higher performance, lighter weight, and more environmentally friendly direction. On the one hand, through advances in materials science, new materials with higher strength, lower weight, and better corrosion resistance have been developed, further enhancing the overall performance of hoses. On the other hand, the continuous optimization and innovation of production processes have significantly improved the production efficiency and quality of hoses. For example, advanced plastic pipe extrusion production lines, hose wrapping production lines, and steel wire weaving machines have been used to achieve automation and intelligence in the hose production process, greatly improving production efficiency and product quality.

The importance of ultra-high pressure resin hoses is increasingly prominent in modern industrial applications. Its quality and performance directly affect the safety and efficiency of production equipment and the entire system. Therefore, it is crucial to choose high-quality and reliable ultra-high pressure resin hoses. High quality hoses not only have excellent performance characteristics, but also provide comprehensive technical support and after-sales service for users, ensuring the safety and reliability of hoses during use.

It is worth noting that although ultra-high pressure resin hoses have many advantages, there are still some precautions to be taken during use. Firstly, suitable hose types and specifications should be selected based on specific application scenarios and requirements. Secondly, during installation and use, it is necessary to strictly follow the operating procedures and safety regulations to avoid unnecessary damage or excessive wear to the hose. Finally, regularly inspect and maintain the hose, promptly identify and address potential issues, and ensure that the hose is in good working condition for a long time.

In summary, as an important component in modern industrial fields, ultra-high pressure resin hoses play an irreplaceable role in promoting industrial development due to their excellent performance characteristics and wide range of applications. With the continuous advancement of technology and deepening of applications, ultra-high pressure resin hoses will demonstrate their unique value in more fields and contribute to the development of modern industry. In the future, we have reason to believe that ultra-high pressure resin hoses will develop towards greater efficiency, intelligence, and environmental protection, bringing more surprises and possibilities to the industrial sector.