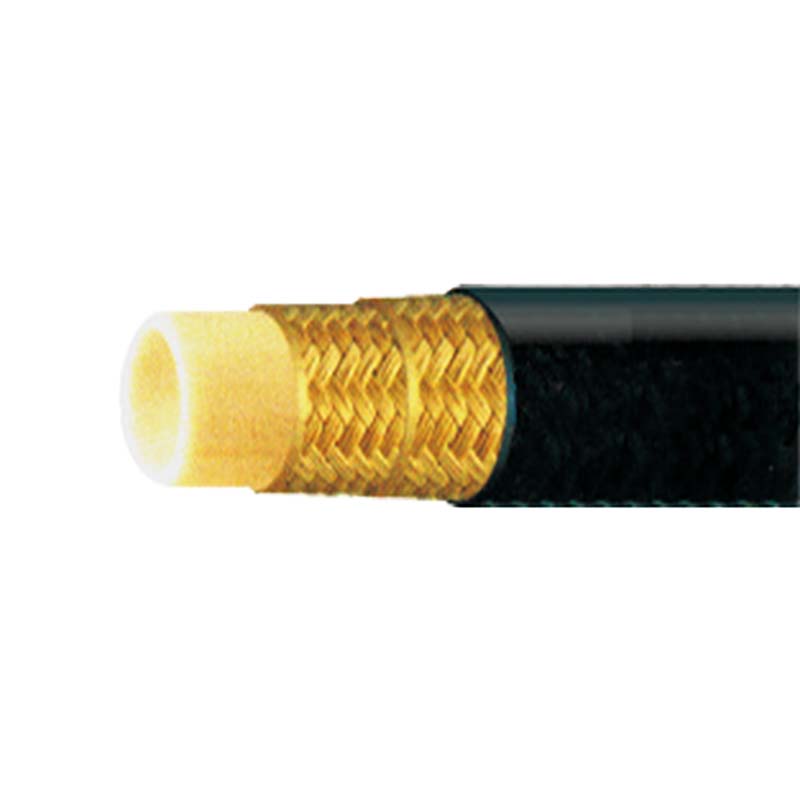

refractory tube Fire resistant hose

In the modern oil and gas industry, the continuous progress and development of drilling technology have led to increasingly high performance requirements for drilling equipment. Especially for drilling equipment working in high-pressure and high-temperature environments, higher requirements have been put forward for the durability and safety of pipelines. Among numerous drilling equipment, the double sealed refractory pipe - a 73mm high-pressure pipe specifically designed for drilling - has attracted much attention due to its excellent performance. This article will comprehensively analyze the structural characteristics, application fields, market prospects, and how to choose suitable products for this type of pipeline.

1、 The structural characteristics of double sealed refractory pipes

The design of the double sealed refractory pipe is extremely unique, mainly composed of an inner pipe and an outer pipe, forming a dual protection between the two. This structure not only improves the pressure resistance of the pipeline, preventing leakage risks caused by high pressure, but also effectively resists the influence of the external environment, making it an indispensable key component in high-pressure drilling systems.

1. High temperature resistant materials: Double sealed refractory pipes are usually made of high-strength alloy materials, which can withstand high temperatures up to 300 degrees Celsius. This characteristic enables it to maintain stable performance under many extreme conditions.

2. Excellent corrosion resistance: Due to frequent exposure to various chemicals during drilling operations, corrosion resistance has become an indispensable indicator for pipelines. The surface of the double sealed refractory pipe has undergone special treatment, greatly enhancing its corrosion resistance and extending its service life.

3. Double seal design: The prominent feature is its double seal design, which effectively prevents oil and gas leakage inside and outside the pipeline, ensuring the safety of operations and environmental protection.

4. Reliable connection method: High pressure pipes usually use advanced threaded connections or welding techniques to ensure that they remain firmly fixed under high pressure, reducing the risk of accidents caused by poor connections.

2、 Application fields of double sealed refractory pipes

Double sealed refractory pipes are widely used in fields such as petroleum, natural gas, geothermal energy development, and mining. In these industries, drilling operations have strict requirements for equipment performance and stability.

1. Oil and gas industry: In oil and gas development, drilling equipment often needs to operate in complex and high-pressure formations. The use of double sealed fire-resistant pipes effectively improves the safety and sustainability of operations, becoming one of the standard equipment in the industry.

2. Geothermal energy development: With the promotion of renewable energy, the development of geothermal energy has become increasingly important. The high-temperature resistant and corrosion-resistant double sealed refractory pipes provide reliable guarantees for geothermal energy extraction, further contributing to environmental protection and sustainable energy development.

3. Mining: Double sealed refractory pipes also play an important role in mining operations. The extraction process of many mineral deposits involves a large amount of liquid and gas, and effective transportation and processing through high-pressure pipelines is the key to ensuring operational efficiency.

3、 Market prospect analysis

With the increasing global demand for energy, the drilling industry is experiencing vigorous development. According to market research, it is expected that the market demand for double sealed refractory pipes will continue to grow in the coming years, driven mainly by the following factors:

1. Energy extraction demand: The global demand for oil and gas continues to rise, directly leading to an increase in demand for related drilling equipment.

2. Technological progress: With the continuous emergence of new technologies, the performance of modern drilling equipment is also constantly improving, and the demand for high-quality high-pressure pipelines will become increasingly evident.

3. Promotion of environmental policies: The increasing emphasis on environmental protection in various countries has led companies to pay more attention to environmentally friendly products when choosing equipment. The double sealed design of fire-resistant pipes conforms to this trend and helps reduce leakage risks, achieving safe production.

4、 How to choose the appropriate double sealed refractory pipe

Choosing the appropriate double sealed refractory pipe is crucial for improving the efficiency and safety of drilling operations. Here are some important factors to consider when making a choice:

1. Material selection: Suitable materials should be selected based on the specific working environment. Materials with strong resistance to high temperatures and corrosion are usually preferred.

2. Pressure level: Before purchasing, it is necessary to clarify the maximum pressure that the pipeline will withstand in your operating environment, so as to choose the appropriate pressure level to ensure that there will be no safety hazards during use.

3. Manufacturer: Choosing a reputable manufacturer is the key to ensuring pipeline quality. Relevant qualifications, market reputation, and past customer feedback should be examined.

4. After sales service: Good after-sales service can provide guarantees for the later operation of enterprises. Attention should be paid to whether the manufacturer provides comprehensive service support, including installation, debugging, maintenance, etc.

5. Cost effectiveness: On the premise of ensuring quality, choose products with high cost-effectiveness to reduce the operating costs of the enterprise and enhance market competitiveness.

conclusion

As a 73mm high-pressure drilling pipe, the double sealed refractory pipe has become a core component of modern drilling operations due to its unique structural design and excellent performance. With the continuous increase in energy demand and technological advancements, the market demand for such pipelines will continue to grow. For enterprises exploring this field in depth, choosing a high-quality double sealed refractory pipe will be the key to achieving safe and efficient operations. Seizing this development opportunity in the booming drilling industry will undoubtedly bring substantial returns to enterprises.