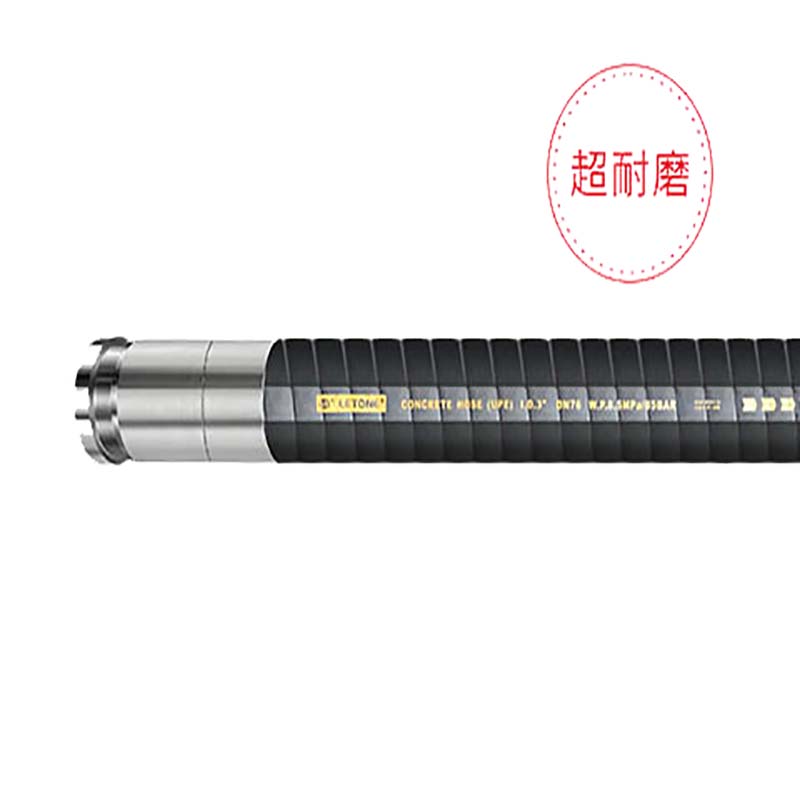

Buckle type rubber hose with stainless steel braided layer

The application of high-pressure oil pipes is very extensive, especially in the fields of hydraulic systems, mechanical equipment, and vehicles. As the core component of hydraulic systems, the performance of high-pressure oil pipe joints directly affects the safety and stability of the entire system. This article will delve into the application characteristics, design principles, material selection points, and installation and maintenance precautions of high-pressure oil pipe joints in a 40MPa pulse resistant environment, helping readers to fully understand this important component.

1、 Definition and importance of high-pressure oil pipe joints

High pressure oil pipe joint refers to the joint that connects high-pressure oil pipes with various hydraulic components. It is mainly used to transport liquids and withstand loads generated by high pressure and pulses. Due to the frequent use of high-pressure oil pipes in harsh working conditions such as high temperature, high pressure, and strong vibration, the quality requirements for joints are particularly strict.

The quality of high-pressure oil pipe joints is not only related to the normal operation of equipment, but also affects the safety of the entire working environment. A high-quality interface can effectively prevent leakage and rupture, ensure stable fluid transport, and thereby improve the efficiency of mechanical equipment.

2、 Design principle of 40MPa pulse resistant joint

1. Design standards

In order to meet the 40MPa pulse resistance requirement, the design of the joint needs to comply with a series of international standards and specifications. For example, standards such as ISO 8434, SAE J514, and DIN 3861 specify performance requirements and testing methods for hydraulic pipe fittings. In the design process, engineers need to carefully consider various factors such as material selection, processing technology, and surface treatment of the product.

2. Material selection

High pressure oil pipe joints are usually made of high-strength alloy steel or stainless steel materials. These materials can withstand high-pressure environments and have good corrosion resistance. When selecting materials, it is also necessary to consider the properties of the liquid to ensure chemical compatibility between the joint material and the liquid. For specific working conditions, corresponding high-temperature or corrosion-resistant materials need to be selected for high temperature or special media to ensure the long-term stable use of the joint.

3. Process requirements

The processing technology of high-pressure oil pipe joints is an important factor determining their performance. High precision machining can ensure the sealing and impact resistance of the joint. In the processing, cold working, heat treatment and other processes are usually used to improve the strength and toughness of the material to achieve better pulse resistance.

3、 Installation and maintenance

1. Correct installation method

When installing high-pressure oil pipe joints, the first step is to ensure the cleanliness of all components and prevent any foreign objects from entering the system, which can ensure the normal flow of fluid and the safe operation of the system. Secondly, install in the correct order, usually by first connecting the oil pipe and then connecting other hydraulic components, ensuring that all connections are securely fastened to prevent leakage under high pressure.

2. Regular inspection and maintenance

High pressure oil pipe joints require regular inspection and maintenance, including checking the wear of the sealing ring, the corrosion of the joint, and whether there is oil leakage. Once an abnormality is detected, the machine should be stopped immediately for testing to avoid more serious consequences. During maintenance, specialized cleaning agents should be used to clean the joints, and sealing materials should be replaced as needed to ensure the good condition of the joints.

4、 Common problems and solutions

1. Joint oil leakage

Joint oil leakage is one of the most common problems for users when using high-pressure oil pipe joints. There may be multiple reasons for oil leakage, including worn sealing rings, loose joints, or aging joint materials. To address these issues, it is necessary to regularly check the condition of the sealing ring and use a torque wrench to ensure the firmness of the installation when tightening the joint.

2. Joint rupture

In extreme high-pressure environments, joints may rupture due to impact loads exceeding their bearing range. To avoid this situation, users should choose validated high-pressure oil pipe fittings and make reasonable selections based on the actual working load of the system. In addition, operators need to be familiar with the working principle of hydraulic systems to avoid overloading operations.

3. Corrosion issues

Impurities and chemicals in liquids may cause corrosion of joints, especially in high temperature or high humidity environments. This requires users to choose alloy materials with strong corrosion resistance as much as possible when selecting materials, and to avoid direct contact with corrosive liquids during use. If necessary, anti-corrosion coatings can be used to protect the joints.

5、 Future Development Trends

With the development of technology and the improvement of industrial technology, the design and manufacturing of high-pressure oil pipe joints are also constantly advancing. In the future, we can foresee the following development trends:

1. Intelligence: By adopting sensor technology, the joint can monitor real-time parameters such as pressure, temperature, and flow rate, and provide timely feedback to the operator to ensure the safe and stable operation of the system.

2. Lightweight: With the advancement of materials science, more and more lightweight and high-strength materials are being used in the manufacturing of high-pressure oil pipe joints, which will effectively reduce the self weight of hydraulic systems and improve overall energy efficiency.

3. Environmental Protection: While focusing on performance, the design of high-pressure oil pipe joints in the future will also increasingly emphasize environmental protection, developing more materials that meet environmental standards and reducing their impact on the environment.

6、 Summary

As an essential component in hydraulic systems, the performance of high-pressure oil pipe joints directly determines the stability and safety of the entire system. Especially under the requirement of 40MPa pulse resistance, the material, design, and manufacturing process of the joint are particularly important. Through scientific and rational selection, installation, and maintenance, users can fully utilize the performance of high-pressure oil pipe joints to ensure the efficient operation of hydraulic systems.

In the future, with the development of technology, we look forward to seeing more intelligent, efficient, and environmentally friendly high-pressure oil pipe joint products appear in various industries, providing stronger guarantees for the reliability and safety of hydraulic systems.