Why is EPDM material the preferred choice for liquid cooled hoses?

In modern automotive and mechanical engineering, liquid cooled hoses are an important component to ensure the normal operation and efficient heat dissipation of equipment. With the advancement of technology and the rapid development of materials science, ethylene propylene diene monomer (EPDM) material has quickly become one of the materials for liquid cooled hoses due to its excellent properties. This article will deeply analyze the superior performance of EPDM materials, especially their outstanding performance in high temperature resistance and coolant resistance, and why they have a place in the market.

1、 Introduction to EPDM material

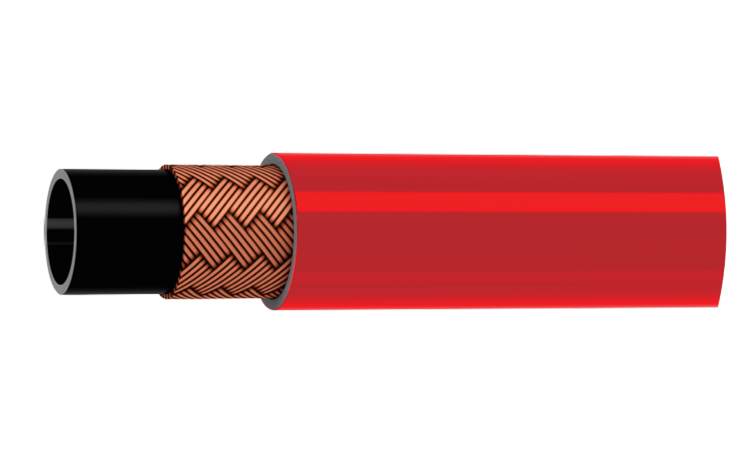

EPDM is a synthetic rubber mainly composed of ethylene, propylene, and a small amount of diene. This material was first widely used in the 1970s due to its excellent weather resistance, wear resistance, corrosion resistance, and good elasticity, and has been widely used in fields such as automotive industry, building materials, and electrical insulation. The physical and chemical properties of EPDM material make it an excellent choice for manufacturing liquid cooled hoses.

2、 High temperature resistance of EPDM material

In liquid cooling systems, hoses are often exposed to high temperature environments. For example, the operating temperature of the engine may reach 150 ℃ or even higher, so liquid cooled hoses must have good high-temperature resistance. The high temperature resistance of EPDM material can usually reach 150 ℃~200 ℃, which allows it to maintain good physical properties under high temperature conditions without plastic deformation or performance degradation.

1. Thermal stability

The molecular structure of EPDM enables it to remain stable in high-temperature fluids and environments, and will not decompose due to high temperatures. This feature ensures the service life and safety of the hose under extreme working conditions.

2. Hot water resistance

EPDM hoses not only resist high temperatures, but also effectively resist the erosion of hot water and steam. This is its major advantage in automotive cooling systems, effectively preventing hose aging and corrosion caused by high-temperature liquid flow.

3. Elasticity and plasticity

In high temperature environments, EPDM material still has good elasticity and plasticity, allowing liquid cooled hoses to withstand various deformations without breaking. This superior flexibility ensures good connection with pumps, joints, and other equipment in practical applications, avoiding damage caused by movement or vibration.

3、 Cooling fluid resistance of EPDM material

The liquid cooling system of a car is usually filled with various coolants, which may contain antifreeze and other chemical components. EPDM material also exhibits excellent chemical stability, especially with good resistance to commonly used automotive coolant.

1. Chemical inertness

EPDM exhibits good compatibility with various chemicals, especially in environments with water, oil, and conventional coolant. Its chemical inertness ensures that the material is not easily corroded or degraded.

2. Low permeability

The low permeability of EPDM hoses can effectively prevent coolant leakage, which is crucial for the cooling system of automobiles. Leakage may not only lead to waste of coolant, but also pose a risk of overheating and damage to the engine.

3. Long term durability

The durability of EPDM is particularly outstanding when in prolonged contact with coolant. This means that liquid cooled hoses can maintain their structural integrity and functional effectiveness under long-term, high-intensity use.

4、 The production process and environmental characteristics of EPDM material

In addition to its superior physical and chemical properties, the manufacturing process of EPDM material is also an environmentally friendly technology that deserves attention. The synthesis process of EPDM is relatively simple and can use renewable resources, which meets the requirements of modern automotive industry for sustainable development.

1. Renewable resources

In the production of EPDM, some raw materials can be sourced from renewable resources to reduce dependence on petrochemical resources. This is of great significance for promoting the green development and environmental awareness of the automotive industry.

2. Recyclability

EPDM has great potential for recycling after use, and can be reprocessed and reused through physical and chemical methods to reduce environmental pollution. In addition, the production process of EPDM produces relatively less harmful substances, making it more environmentally friendly.

5、 Advantages of EPDM material in the liquid cooled hose market

In summary, EPDM material has significant advantages in the application of liquid cooled hoses, mainly manifested in the following aspects:

-Excellent high temperature resistance

-Good resistance to coolant performance

-Significant economy and durability

-Environmentally friendly production process

These characteristics have made EPDM liquid cooled hoses widely used in the market, especially in high-performance automobiles, heavy machinery, and aviation technology, becoming an important component of liquid cooling systems.

VI. Conclusion

With the continuous advancement of technology, the demand for liquid cooled hoses will continue to grow. EPDM material has become the preferred material for liquid cooled hoses due to its various advantages such as high temperature resistance, coolant resistance, and environmental friendliness. In the future, EPDM will play an important role in more fields, promoting more efficient and environmentally friendly development in the automotive and machinery industries.

Therefore, for engineers, manufacturers, and consumers who want to improve the performance of liquid cooling systems, choosing EPDM material for liquid cooling hoses is undoubtedly a wise choice. It not only provides reliable performance guarantees, but also contributes to sustainable development.