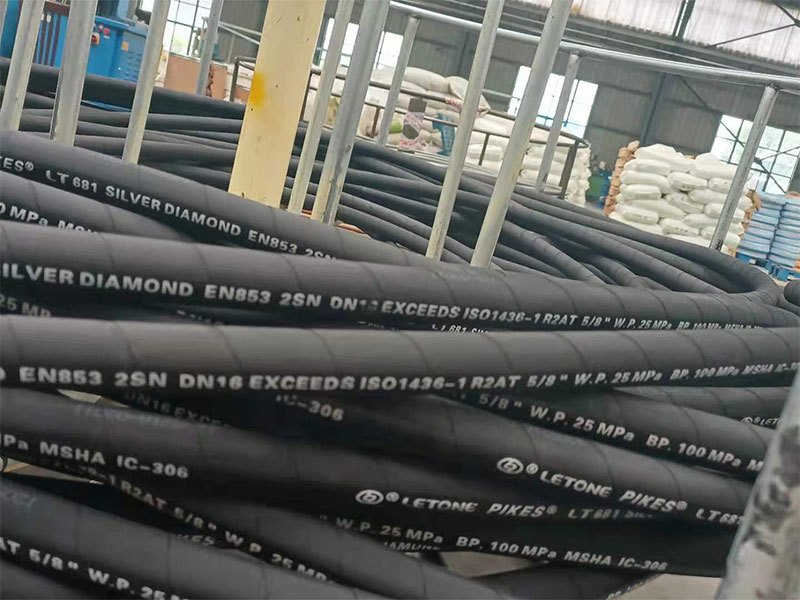

Steel wire wrapped hydraulic hose

In modern mechanical operations, the performance of hydraulic systems is crucial. Whether on excavators, shovels, or other heavy machinery, the quality of hydraulic oil pipes directly affects the efficiency and safety of the equipment. Especially in high-pressure environments, choosing a high-quality national standard certified 6SP high-pressure hose and steel wire wrapped hydraulic hose is a key factor in ensuring the normal operation of the hydraulic system. This article will delve into the characteristics, applications, and selection guidelines of these two types of hydraulic hoses to help you better replace and maintain hydraulic oil pipes for excavators and shovels.

1、 Advantages of 6SP High Pressure Hose with National Standard Certification

The Importance of National Standard Certification

National standard certification refers to a quality certification system that ensures the safety and reliability of products in accordance with national standards. 6SP high-pressure hoses comply with national standards and have undergone strict inspections on materials and processes to ensure their performance in high-pressure environments.

2. Excellent pressure resistance performance

The national standard certified 6SP high-pressure hose is made of high-quality materials and has super strong pressure resistance, usually able to withstand pressures up to 42MPa. This high pressure resistance performance makes it widely used in various heavy-duty mechanical equipment, especially in construction sites, where it can withstand extreme hydraulic impacts and pressure fluctuations, ensuring work efficiency.

3. Excellent wear and oil resistance

The wear resistance and oil resistance of high-pressure hoses determine their performance in harsh environments. The outer layer of the 6SP high-pressure hose is made of rubber material, which can resist the wear and tear of substances such as stone and sand. In addition, its excellent oil resistance enables hydraulic oil to remain stable in high temperature, low temperature, and various chemical environments, reducing the occurrence of oil leakage.

4. Flexibility and operability

6SP high-pressure hose is not only pressure resistant, but also has good flexibility, making installation and operation very convenient. Even in small spaces or complex environments, it can still be easily placed, thereby improving the flexibility and efficiency of construction.

2、 Characteristics of Steel Wire Wrapped Hydraulic Rubber Hose

1. The superiority of structural design

The steel wire wrapped hydraulic hose adopts a special multi-layer structure, with the inner layer made of oil resistant rubber, the middle woven from high-strength steel wire, and the outer layer made of wear-resistant outer skin. This design gives it extremely high tensile strength and wear resistance, and is widely used in fields such as engineering machinery and agricultural machinery.

2. Significant high temperature resistance performance

Hydraulic oil generates heat during operation, and if the temperature is too high, it can affect the efficiency and lifespan of the hydraulic system. The material combination of steel wire wrapped rubber hose enables it to have good high temperature resistance and can work stably for a long time in high temperature environments.

3. Excellent anti-aging ability

During long-term use, materials may experience aging due to factors such as ultraviolet radiation and oxidation. The steel wire wrapped hydraulic hose has been specially treated to prevent aging, extend its service life, and reduce the trouble of frequent replacement.

3、 The importance of replacing hydraulic oil pipes

1. Ensure the normal operation of the equipment

Regular inspection and replacement of aged or damaged hydraulic oil pipes are important steps to ensure the normal operation of equipment. If the oil pipe leaks or ruptures, it will inevitably affect the output of the hydraulic system, causing equipment shutdown and unnecessary economic losses. Therefore, choosing high-quality hydraulic oil pipes for replacement is crucial.

2. Improve homework safety

During high-intensity operation, any minor malfunction in hydraulic systems can potentially lead to significant safety hazards. High quality national standard certified 6SP high-pressure hoses and steel wire wrapped hydraulic hoses can effectively reduce the risk of accidents. By timely replacing old oil pipes, you not only ensure the efficient operation of the machinery, but also provide a guarantee for the safety of the operators.

4、 How to choose the appropriate hydraulic oil pipe?

1. Confirm specifications

When selecting hydraulic oil pipes, it is necessary to first confirm their specifications, including length, diameter, etc. These parameters directly affect the effectiveness and adaptability of the tubing. Ensure that the purchased oil pipes meet the actual needs of the equipment to avoid mismatches during installation.

2. Check the materials

Secondly, when selecting oil pipes, attention should be paid to their material. The high-pressure hoses and steel wire wrapped hydraulic hoses certified by national standards have undergone strict material control to avoid safety hazards caused by substandard materials. Therefore, choosing these certified products is a wise decision.

3. Understand the brand

There are many brands of hydraulic oil pipes on the market, and choosing a reputable brand can ensure product quality. Famous brands usually have a comprehensive after-sales service system, and if they encounter problems during use, they can receive timely assistance.

4. Consider the work environment

The requirements for hydraulic oil pipes vary depending on the working environment. If the machinery needs to work in high temperature, high pressure, or corrosive environments, it is necessary to choose oil pipes with corresponding characteristics to ensure that they can withstand harsh working conditions.

summary

In the use of hydraulic equipment such as excavators and shovels, the national standard certified 6SP high-pressure hose and steel wire wrapped hydraulic hose are undoubtedly the best choices. They not only have excellent pressure resistance and wear resistance, but also can maintain stable working conditions in high temperature and high pressure environments. Regular inspection and replacement of hydraulic oil pipes are important measures to ensure efficient and uninterrupted operation of equipment, ensure construction safety, and appropriate purchasing decisions are the responsibility and obligation of every mechanical equipment user.

By choosing high-quality hydraulic oil pipes, you are ensuring the smooth progress of the project. Whether for daily maintenance or in case of equipment failure, high-quality hydraulic hose products will help you operate efficiently and continuously climb the peak of your career.