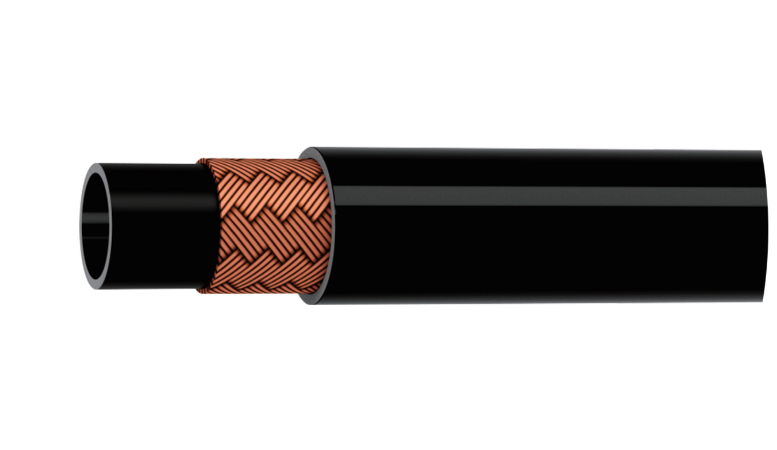

EPDM inner rubber layer for new energy liquid cooled hoses

In the field of new energy vehicles, the effectiveness of heat management is crucial for the overall performance, durability, and safety of the vehicle. New energy vehicles have increasingly high requirements for cooling systems due to the high heat generated by their high-performance batteries and electric motors during operation. To address this challenge, new energy liquid cooled hoses have emerged. Among them, liquid cooled hoses with EPDM inner rubber layer have become the darling of the market due to their excellent anti leakage ability and coolant resistance.

1、 The Importance of Liquid Cooling Systems

The liquid cooling system in new energy vehicles is mainly used to cool the battery pack and electric motor, which generate a large amount of heat during operation. If the cooling is not effective, it may cause the battery temperature to be too high or even damaged, affecting the vehicle's endurance and safety. Therefore, the design and implementation of liquid cooling systems are crucial.

As a key component of the cooling system, liquid cooled hoses play an important role in transporting coolant. If there are problems such as leakage in the hose, it may cause the loss of coolant, resulting in the entire cooling system not working properly, which seriously affects the performance and safety of the car.

2、 Advantages of EPDM material

EPDM (ethylene propylene diene monomer rubber), as the inner rubber layer material of liquid cooled hoses, has many advantages, making it highly favored in the cooling system of new energy vehicles.

1. Excellent heat resistance: EPDM has high temperature resistance and can be used for a long time in high temperature environments without deformation or aging. This feature enables EPDM liquid cooled hoses to adapt to the high temperature output of components such as new energy vehicle engines.

2. Good chemical resistance: Coolant often contains multiple chemical components, and EPDM has good resistance to various chemicals, which can effectively prevent reactions between coolant and hose materials, thereby ensuring the long-term stability of the cooling system.

3. Excellent elasticity and flexibility: EPDM material is rich in elasticity, which allows liquid cooled hoses to maintain good shape under high pressure and is not easily broken. Meanwhile, its flexibility makes installation more convenient and adaptable to compact spatial layouts.

4. Excellent anti leakage performance: The tight structure and high-density characteristics of the EPDM inner layer can effectively prevent coolant leakage and ensure the normal operation of the cooling system. The solution to the leakage problem not only improves the reliability of the entire vehicle, but also reduces the frequency of repairs and enhances the driving experience for car owners.

3、 Practical application of new energy liquid cooled hoses

In the cooling systems of many new energy vehicles, such as electric SUVs and pure electric vehicles, liquid cooled hoses with EPDM inner rubber layers have been widely used. Taking a well-known electric SUV as an example, this technology is used in its cooling system to meet the increasing demand for improved vehicle performance in the fiercely competitive market.

In actual testing, the leakage rate of coolant is almost zero when using liquid cooled hoses with EPDM inner rubber layer. After more than 3000 kilometers of testing, the stability and durability of the coolant have been fully validated, proving that this material can maintain efficient operation under various extreme driving conditions.

4、 Future Development Trends

With the continuous development of the new energy vehicle market, the demand for liquid cooled hoses will also continue to grow. In the future, in addition to EPDM materials, other new materials such as silicone rubber and fluororubber may also be developed and applied to the inner rubber layer of liquid cooled hoses. These materials each have different advantages and are expected to further promote the advancement of cooling management technology.

Meanwhile, the continuous improvement of production processes will also enhance the performance of liquid cooled hoses. For example, using new composite materials to enhance the wear resistance and pressure resistance of hoses, in order to meet the increasingly strict requirements of future automotive technology for components.

In addition, with the increasing awareness of environmental protection, the performance of new energy vehicles is no longer solely dependent on power and range. Reducing the impact on the environment and improving the recyclability of materials will also become future trends. Manufacturers of liquid cooled hoses may focus on finding more environmentally friendly materials and production processes while ensuring performance.

5、 Summary

Overall, new energy liquid cooled hoses, especially those using EPDM inner rubber layers, have become an important innovation in the cooling system of new energy vehicles. Faced with increasingly fierce market competition, automobile manufacturers must pay attention to the material selection of liquid cooled hoses and their impact on the overall performance of cooling systems. Only in this way can we stand undefeated in the fierce market and provide consumers with a safer and more reliable experience of new energy vehicles.

In the future, liquid cooled hoses will continue to innovate with the development of new materials and the application of new technologies, welcoming new challenges and opportunities in the automotive industry. With the continuous advancement of new energy technology, we have reason to believe that the liquid cooled flexible tubing with EPDM inner rubber layer will become an important component of more electric vehicle systems in the future, driving the entire industry towards higher standards.