High temperature resistant ethylene glycol water solution hose

The reliability and performance of cooling systems are crucial in industries such as automotive and electronic devices. With the advancement of technology, the material of hoses in cooling systems has also been significantly improved, especially high-strength liquid cooled hoses used in high temperature and high pressure environments. The inner layer of this hose is made of EPDM rubber (ethylene propylene diene monomer), which provides excellent high temperature resistance and leakage prevention performance for the product. This article will comprehensively introduce the characteristics, advantages, and application fields of high-strength liquid cooled hoses, and deeply explore the important role of EPDM rubber in them.

What is high-strength liquid cooled hose?

High strength liquid cooled hose is a type of hose designed specifically for high-temperature and high-pressure liquid transmission, widely used in automotive cooling systems, industrial equipment, and electronic product cooling devices. Its design purpose is to ensure that the liquid does not leak during operation, thereby ensuring the normal operation and service life of the equipment. Traditional hoses are prone to deformation or rupture under high temperature and pressure conditions, while high-strength liquid cooled hoses effectively overcome these problems with their advanced materials and structural design.

Advantages of EPDM rubber

EPDM rubber is a synthetic rubber mainly composed of ethylene propylene diene, which has good heat resistance and excellent oxidation resistance. This makes EPDM an ideal choice for the inner layer of high-strength liquid cooled hoses. Specifically, the advantages of EPDM rubber include:

1. High temperature resistance: EPDM rubber can work stably under high temperature conditions above 170 ℃, and is not easily deformed or lose its original properties. This enables high-strength liquid cooled hoses to be used in high-temperature environments such as engines for a long time without performance degradation due to excessive temperature.

2. Chemical corrosion resistance: EPDM rubber has excellent resistance to many chemicals, including oxidants, acids, alkalis, etc., and is suitable for transporting petroleum, fuels, and other liquids.

3. Excellent aging resistance: EPDM rubber has strong resistance to ultraviolet and ozone aging under normal use conditions, which can effectively extend the service life of liquid cooled hoses.

4. Excellent elasticity and sealing performance: EPDM rubber has excellent elasticity and can maintain good sealing performance under high pressure. This is crucial for preventing leakage.

Structural Design of High Strength Liquid Cooled Hose

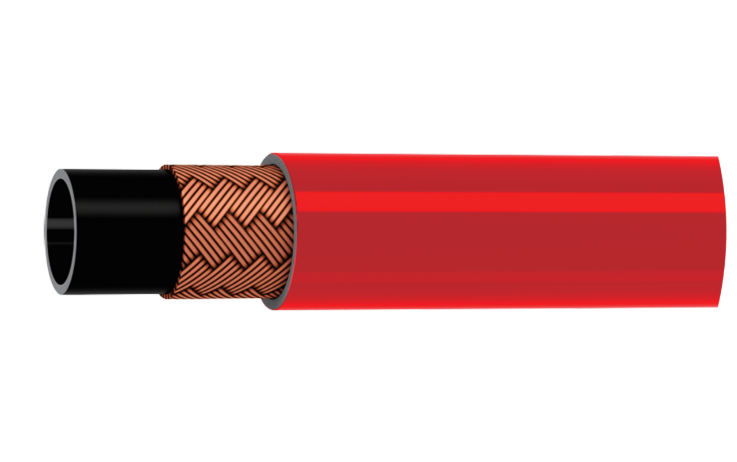

The design of high-strength liquid cooled hoses typically includes multiple layers of structure to provide stronger strength and durability. Its typical structure includes:

-Inner layer: Made of EPDM rubber, providing high temperature resistance and sealing performance.

-Reinforcement layer: usually made of high-strength fabric or coil material, which increases the compressive strength and wear resistance of the hose.

-Outer layer: The outer layer material can be wear-resistant polyurethane or other synthetic materials, providing additional protection against external environmental influences.

This multi-layer design not only provides the flexibility of a free whole, but also allows liquid cooled hoses to work safely and stably under high pressure and high temperature conditions.

Application field

High strength liquid cooled hoses are widely used in multiple fields due to their excellent performance:

1. Automotive industry: Liquid cooled hoses are an indispensable part in engine cooling systems, transmission cooling, turbocharging systems, and other areas. It can effectively deliver coolant to the components that need to be cooled, thereby ensuring the performance and service life of the engine.

2. Aerospace and aviation: In the aerospace field, liquid cooled hoses can be used for thermal conductivity and cooling systems, especially under extreme environmental conditions. The high temperature resistance of EPDM rubber is crucial for the safety of spacecraft.

3. Metallurgical industry: Controlling liquid temperature is particularly important in high-temperature environments such as smelting and forging. High strength liquid cooled hoses can work stably under floating high temperature and pressure conditions.

4. Electronic devices: With the increasing demand for heat management in electronic products, liquid cooled hoses are also widely used in cooling systems for high-performance computers and data centers.

5. Renewable energy: In the cooling of wind power, solar photovoltaic, and battery systems, liquid cooled hoses are particularly important, as they help improve equipment efficiency and extend lifespan.

Maintenance and Care

Proper maintenance and upkeep are also essential to ensure the long-term performance of high-strength liquid cooled hoses. Here are some suggestions:

1. Regular inspection: Regularly inspect the surface condition of the hose to ensure that there are no cracks, deformations, or other damages. If any problems are found, they should be replaced in a timely manner.

2. Temperature monitoring: When used in high temperature environments, it is necessary to monitor the temperature of the system to ensure that it does not exceed the tolerance limit of the hose.

3. Avoid excessive bending: During installation, avoid excessive bending or twisting of the hose, as this may cause damage to the internal structure.

4. Regular replacement: Although EPDM rubber has excellent durability, it is still recommended to regularly replace liquid cooled hoses to ensure optimal system performance.

Conclusion

High strength liquid cooled hoses, as an important component of modern cooling systems, are driving the development of various industries due to the high temperature resistance and leak resistance advantages of their inner EPDM rubber layer. With the advancement of technology and the increase in industrial demand, the application of liquid cooled hoses will become increasingly widespread, and their key performance will continue to be improved. Choosing high-quality liquid cooled hoses can not only improve the operational efficiency of equipment, but also save maintenance and replacement costs for enterprises in the long run. Therefore, understanding the performance characteristics and usage precautions of high-strength liquid cooled hoses is essential for professionals in various industries.

Through in-depth analysis of high-strength liquid cooled hoses, we can better understand the importance and potential value of this product in practical applications. Choosing the appropriate liquid cooled hose will lay a solid foundation for the safety and efficiency of the equipment.