HPP non thermal processing replaces pasteurization

Ultra high pressure HPP cold sterilization equipment: a new choice for non thermal processing that overturns traditional pasteurization

Ensuring food safety and extending shelf life are crucial in the modern food processing industry. This goal has traditionally relied on pasteurization, but with the increasing demand for food quality from consumers, ultra-high pressure cold sterilization technology (HPP) has gradually become a new favorite in the industry. This article will delve into the working principle, advantages, applications in different industries, and future market prospects of ultra-high pressure HPP cold sterilization equipment.

1、 Overview of Ultra High Pressure Cold Sterilization Technology

High Pressure Processing (HPP) is a non thermal processing technology that utilizes high pressure to treat food. This technology is used in the food processing process, where the product is encapsulated in a high-pressure environment, typically with a working pressure between 300 and 600 megapascals (MPa) and a processing time of several minutes. This method can effectively kill various bacteria, yeast, and mold while maintaining the nutritional content and flavor of the food.

2、 Working principle of HPP cold sterilization

The core of HPP cold sterilization lies in applying uniform high pressure to food. Under high pressure, the cell membrane of microorganisms undergoes structural changes, leading to leakage of cellular contents and achieving bactericidal effects. Unlike traditional heat treatment, HPP technology only processes food under pressure rather than applying heat, thus better preserving the original color, taste, and nutritional content of the food.

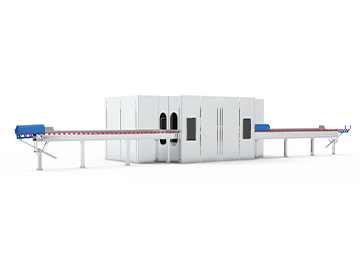

In the HPP process, the food is first sealed in specialized packaging materials and then placed in a high-pressure tank. Using water as a transfer medium, pressure is transmitted to the food through a specific pump, and the entire process is usually completed within 30 seconds to a few minutes, depending on the degree of pressure and the type of food. Subsequently, the pressure is quickly released, and the food can be removed for further processing or packaging.

3、 The advantages of ultra-high pressure HPP cold sterilization

1. Preserve nutritional components

The traditional pasteurization method often requires high-temperature treatment, which has a destructive effect on certain vitamins and nutrients in food. And HPP technology, due to being carried out at low temperatures, can maximize the retention of the original nutrients and active ingredients of food.

2. Effective sterilization

HPP technology can kill various pathogens, including Escherichia coli, Salmonella, Listeria, etc., providing great protection for food safety. Meanwhile, HPP also exhibits good inhibitory effects on heat-resistant bacteria and spores.

3. Increase shelf life

Food processed through HPP can greatly extend its shelf life. This advantage reduces the risk of food spoilage during transportation and storage, saving costs for food manufacturers.

4. Environmental protection technology

The HPP cold sterilization process mainly uses water as the transfer medium and does not require the addition of chemical additives, making it relatively environmentally friendly. Meanwhile, the energy consumption of HPP equipment is lower compared to traditional thermal sterilization equipment.

4、 Market Application of Ultra High Voltage HPP Equipment

1. Juice and beverage industry

With consumers' preference for natural, additive free foods, the juice and beverage industry is gradually adopting HPP technology for sterilization. HPP can preserve the freshness and nutrition of fruit juice, while avoiding flavor changes caused by heat treatment, and is highly popular in the market.

2. Meat and seafood processing

In the processing of meat and seafood, HPP technology can effectively remove pathogenic bacteria while maintaining the freshness of the food. More and more meat products and ready to eat seafood products are being processed using HPP technology, which has improved the safety and market competitiveness of the products.

3. Plant based foods

With the popularity of plant-based foods, HPP technology provides a new option for the production of plant-based products. Many plant-based meat substitutes, seasonings, or ready to eat foods are using HPP technology to ensure food quality and safety.

4. Dairy industry

HPP technology also performs well in dairy processing, effectively extending the shelf life of dairy products without affecting their flavor and nutrition. Many foreign small family workshops and large dairy companies have begun to pay attention to the important role of HPP in increasing product value.

5、 Future Development Trends

With the increasing demand for healthy and natural foods among consumers, the HPP cold sterilization equipment market is expected to continue expanding. According to market research, ultra-high pressure processing technology will be applied in more food fields in the coming years. In addition, with the continuous advancement of technology, the cost of HPP equipment will be further reduced, promoting its popularization in small and medium-sized enterprises.

Meanwhile, research and innovation will also be important driving forces for the development of HPP technology. By combining new materials, equipment, and biotechnology, improving the efficiency and effectiveness of HPP processes will become an important direction for industry development.

VI. Conclusion

The ultra-high pressure HPP cold sterilization equipment is gradually overturning the traditional pasteurization method with its excellent sterilization effect and high preservation of food quality. Its widespread application in fields such as fruit juice, meat products, dairy products, etc. demonstrates the irreplaceable advantages of HPP technology. With the increasing market demand and technological progress, the future prospects of ultra-high pressure cold sterilization technology are worth looking forward to, which will bring more possibilities to the modern food processing industry.

By gaining a deeper understanding of HPP technology, relevant enterprises can better grasp market trends, improve product quality, and meet consumers' pursuit of healthy food. In the future, HPP cold sterilization equipment will provide food safety and quality control, promoting healthier development of the industry.