Flexible hoses for liquid cooling system in computer room

In the current era of rapid development of the digital economy, data centers serve as the core hub of computing power, and server operating loads continue to rise. Heat dissipation efficiency has become a key factor affecting the stable operation and energy consumption control of equipment. The liquid cooling system in the data center has gradually replaced traditional air cooling as the preferred solution for high-end data centers due to its advantages of efficient heat dissipation, energy saving and consumption reduction. The server cooling hose and the liquid cooling system hose in the data center, as the "blood vessels" of the liquid cooling system, bear the core responsibility of transporting the coolant, directly determining the stability and reliability of the entire cooling system.

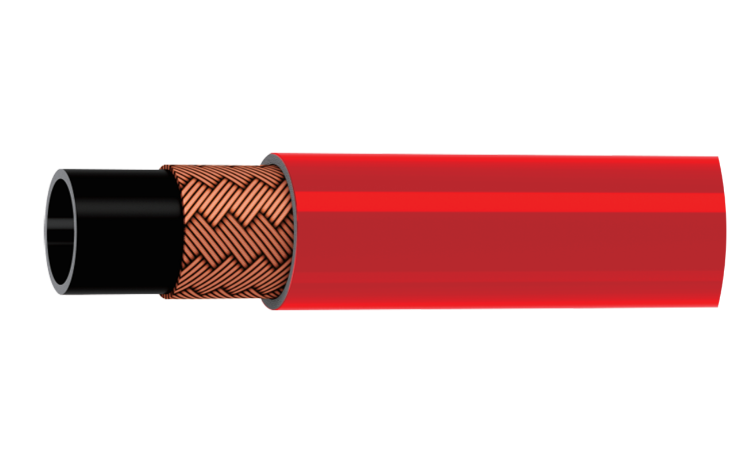

The server cooling hose is a flexible transmission component that adapts to the heat dissipation needs of various servers. It belongs to the core component of the liquid cooling pipeline along with the liquid cooling system hose in the computer room. The two complement each other according to the differences in application scenarios, jointly supporting the efficient operation of the computer room heat dissipation system. Unlike ordinary industrial hoses, this type of hose needs to meet the strict operating environment requirements of data centers, with core characteristics such as high temperature resistance, high pressure resistance, corrosion resistance, low leakage, and strong flexibility. It can adapt to the complex wiring space in the computer room and resist the loss caused by long-term flushing of the coolant, ensuring efficient circulation of the coolant in the closed pipeline and timely removal of heat generated by core components such as server CPUs and GPUs.

The hose of the liquid cooling system in the computer room is mainly used for the connection and extension of the overall liquid cooling pipeline in the computer room, covering mainstream liquid cooling solutions such as cold plate liquid cooling and immersion liquid cooling. It can be connected to the cooling distribution unit (CDU), cabinet manifold, and server terminal to achieve global circulation and transmission of cooling liquid. Its flexible design can effectively absorb the stress caused by building settlement, equipment vibration, and thermal expansion and contraction of pipelines in the computer room, avoid pipeline breakage or leakage, and facilitate later equipment maintenance and pipeline renovation, greatly reducing operation and maintenance costs. The server cooling hose, on the other hand, focuses more on terminal adaptation, accurately connecting the internal heat dissipation module of the server with the liquid cooling main pipeline of the computer room. It is compact in size and has a small bending radius, allowing it to flexibly shuttle through the narrow space inside the server without occupying the installation position of core components, balancing heat dissipation efficiency and equipment compatibility.

Currently, with the tightening of PUE value control in data centers, the large-scale application of liquid cooling systems in data centers is driving the accelerated upgrading of the server cooling hose industry. The mainstream products are made of high-quality materials such as EPDM rubber and FEP fluoroplastic. Among them, EPDM rubber hoses are widely used in liquid cooling scenarios for medium and low power servers due to their cost advantages and excellent flexibility; FEP corrugated pipes are suitable for immersion liquid cooling systems due to their excellent chemical corrosion resistance and transparency, making it easy to observe the flow of coolant. At the same time, the production process of hoses continues to be optimized, and the application of integrated molding and seamless connection technology has greatly improved the sealing of pipelines. The leakage rate is controlled at an extremely low level, effectively avoiding damage to server equipment caused by coolant leakage.

In practical applications, the reasonable combination of server cooling hoses and machine room liquid cooling system hoses can significantly improve the heat dissipation efficiency of the machine room liquid cooling system. For example, a large Internet data center adopts the cold plate liquid cooling scheme. By deploying customized machine room liquid cooling system hoses to connect the CDU with the cabinet, and cooperating with the server cooling hoses to achieve the docking of terminal heat dissipation modules, the overall PUE value of the machine room is reduced to below 1.1, and the stability of server operation is improved by 30%, which can save a lot of energy costs every year. In addition, this type of hose also has good compatibility and can be adapted to servers and liquid cooling equipment of different brands and specifications. It can be upgraded and iterated without large-scale renovation, meeting the needs of data center computing power expansion.