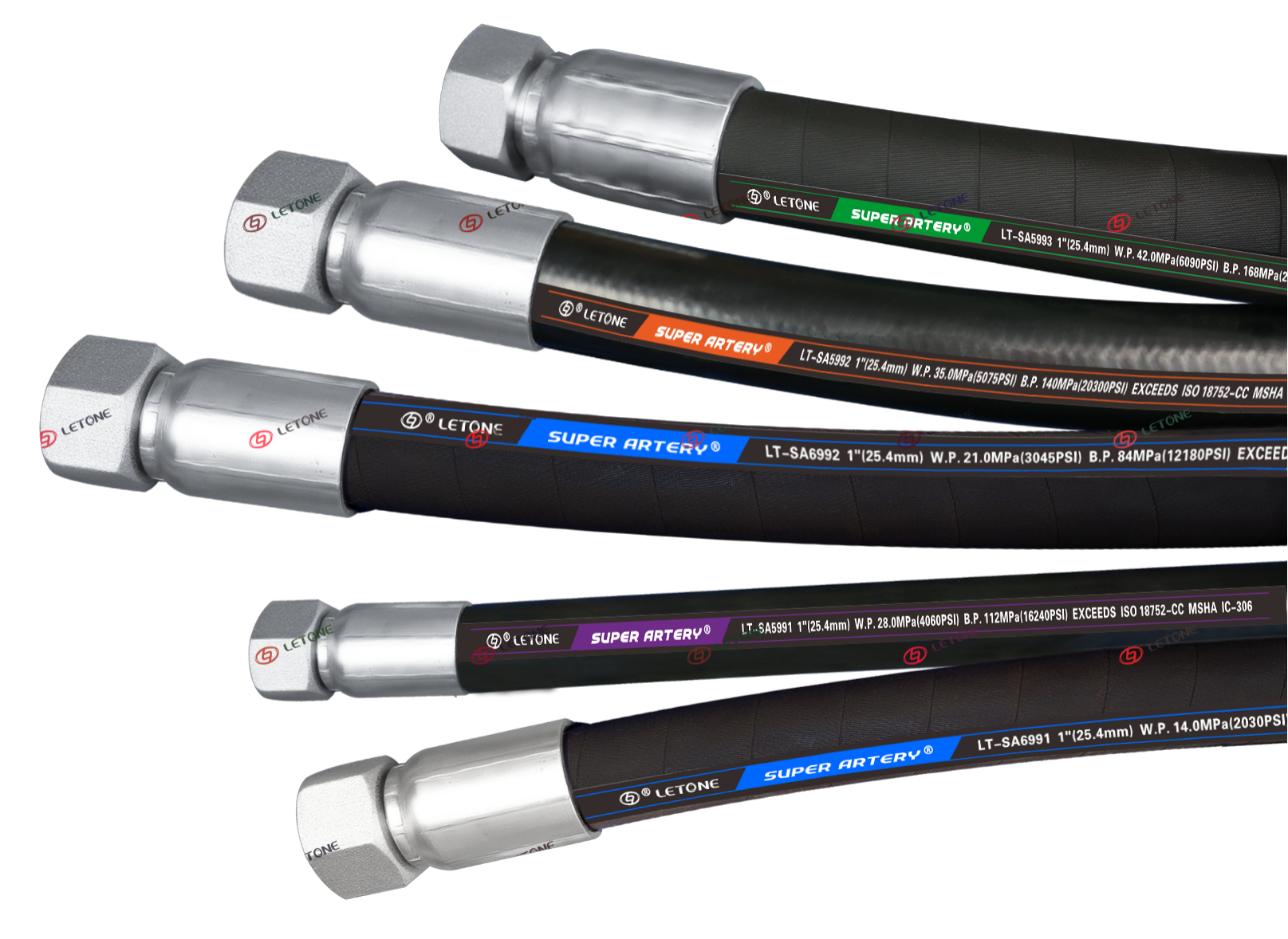

Super strong pulse hose, non stripping and wear-resistant hydraulic hose

In the construction machinery industry, a reliable hydraulic system is the key to ensuring efficient operation of equipment, and high-pressure oil pipes play a crucial role as an important component of the hydraulic system. This article will delve into the characteristics, applications, and importance of high-pressure oil pipes in construction machinery, especially four layer steel wire wound hoses.

1、 Basic concepts of high-pressure oil pipes

High pressure oil pipe is a pipeline used for transmitting hydraulic oil, which needs to withstand high pressure force and effectively resist high temperature, corrosion, and external impact. High pressure oil pipes are mainly composed of multiple parts such as inner layer, reinforcement layer, and outer layer, among which the design of the reinforcement layer determines the compressive strength and durability of the pipeline.

2、 Construction of four layer steel wire wrapped flexible hose

A four layer steel wire wrapped hose is composed of four layers of material, usually consisting of an inner layer of rubber, two layers of steel wire, and an outer layer of rubber. The specific structure is as follows:

1. Inner layer rubber: High quality rubber is selected as the inner layer material, which has good oil resistance and wear resistance, and can effectively prevent hydraulic oil leakage.

2. Steel wire reinforcement layer: The two layers of steel wire in the middle are wound at different angles, providing higher compressive and tensile strength. This design enables the hose to withstand frequent pressure fluctuations and operational loads, enhancing its stability and safety.

3. Outer rubber: The outer layer is also made of high-quality rubber material, which has excellent wear resistance, oil resistance, and weather resistance, effectively protecting the internal structure from external environmental influences.

3、 Working principle of high-pressure oil pipe

The working principle of high-pressure oil pipes is to transmit force through the flow of hydraulic oil in the pipeline. Hydraulic oil is pumped through an oil pump to a high-pressure oil pipe, where it is transmitted under high pressure and ultimately drives the movement of the mechanical device. Due to the frequent need for high power and efficiency in the operation of construction machinery, the transmission speed and stability of hydraulic oil pipes are particularly important.

4、 The superiority of four layer steel wire wrapped hose

The design of the four layer steel wire wrapped hose gives it unparalleled advantages in various aspects compared to other types of hoses:

1. High compressive performance: The four layer steel wire design enables it to withstand extremely high internal pressure, making it suitable for various high-pressure hydraulic systems and effectively preventing pipe burst risks.

2. Wear resistance and durability: The outer rubber provides excellent protection against wear and environmental erosion, allowing the hose to maintain a long-lasting service life even under harsh working conditions.

3. Flexibility: Despite its strong high-pressure performance, the four layer steel wire wrapped hose still maintains relatively good flexibility and can adapt to complex installation environments and space limitations.

4. Corrosion resistance: The material selection and design take into account the corrosiveness of hydraulic oil, which can maintain stable performance even in environments containing corrosive liquids.

5. Economy: Due to its excellent durability and long service life, the four layer steel wire wrapped hose has relatively low maintenance costs during long-term use, which overall improves economic benefits.

5、 Application of High Pressure Oil Pipes in Construction Machinery

High pressure oil pipes are widely used in various types of construction machinery, including excavators, forklifts, bulldozers, milling machines, etc. They are responsible for transmitting hydraulic oil in the hydraulic system and driving the movement of various actuating components. Specific applications include:

1. Hydraulic excavator: In the excavator, the high-pressure oil pipe is responsible for transmitting hydraulic oil to the cylinder, allowing the excavation arm, bucket and other components to move flexibly, thereby completing excavation, handling and other operations.

2. Hydraulic bulldozer: Bulldozers are often used in heavy-duty work, and ensuring the stability of the hydraulic system and the performance of the high-pressure oil pipe is directly related to the operational efficiency of the machinery.

3. Hydraulic lifting equipment: In various lifting platforms or forklifts, four layer steel wire wrapped hoses are widely used, which can withstand a large amount of pressure and ensure the safe operation of the equipment when lifting heavy objects.

6、 Maintenance and replacement of high-pressure oil pipes

Regular inspection and maintenance are essential to ensure the long-term stable operation of high-pressure oil pipes. Specific maintenance suggestions include:

1. Regularly inspect the pipeline: observe whether the hose is damaged or aged, and replace it immediately if any problems are found.

2. Maintain the sealing at the joint: Check for any leakage at the joint and replace the sealing ring if necessary.

3. Regular oil replacement: Keep the hydraulic oil clean and regularly replace the oil to avoid affecting pipeline performance due to oil contamination.

4. Pay attention to environmental factors: Try to avoid exposing high-pressure oil pipes to high temperatures, strong sunlight, or corrosive environments.

7、 Summary

As an important type of high-pressure oil pipe for construction machinery, the four layer steel wire wrapped hose has been widely used due to its excellent performance and economic benefits. Through continuous maintenance and reasonable use, its service life can be effectively extended, ensuring the efficient and safe operation of construction machinery in various complex environments. In the future, with the continuous advancement of technology in the engineering industry, the performance and application fields of four layer steel wire wound hoses will also continue to expand, providing strong support for the vigorous development of construction machinery.