Coal mine support hydraulic hose, comprehensive mining unit

In modern coal mining processes, safety issues are particularly important. In order to improve the safety and efficiency of coal mining operations, the application of various equipment is becoming increasingly widespread. Among them, hydraulic hoses are an indispensable part of coal mining machinery equipment, and their importance is self-evident. Among numerous hydraulic hoses, MSHA certified hydraulic hoses have become the choice for equipment such as coal mine supports due to their excellent performance and safety assurance.

1、 The significance of MSHA certification

MSHA (Mine Safety and Health Administration) certification is a safety certification for mining equipment and materials. This type of certification aims to ensure the performance of equipment under extreme conditions, including high temperature, high pressure, etc. For coal mine hydraulic hoses, MSHA certification means that their materials must have excellent wear resistance, corrosion resistance, and pressure resistance. This not only improves the service life of the equipment, but also effectively avoids safety hazards caused by equipment failures.

2、 Basic structure of hydraulic hoses

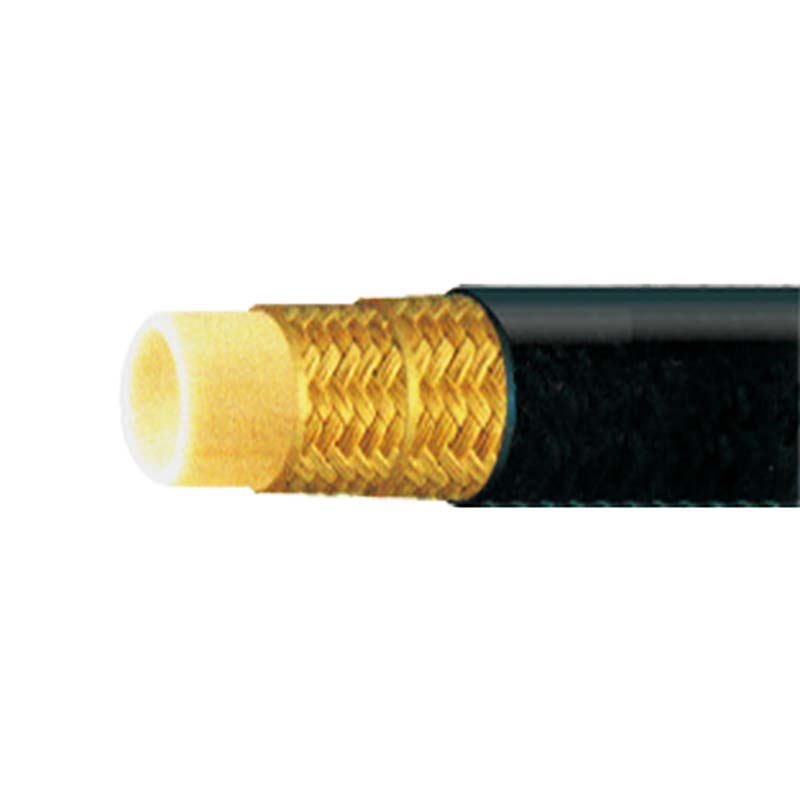

Hydraulic hoses generally consist of three parts: inner layer, reinforcement layer, and outer layer.

1. Inner layer: The inner layer is the core of hydraulic hoses, usually made of synthetic rubber or polyurethane. Its function is to carry liquid pressure and provide good sealing to prevent fluid leakage.

2. Reinforcement layer: The reinforcement layer is generally woven from multiple strands of high-strength fibers (such as steel wire or synthetic fibers). The main function of this layer is to enhance the pressure and tensile resistance of the hose, so that it can work normally in high-pressure environments without deformation or rupture.

3. Outer layer: The outer layer is usually made of wear-resistant, oil resistant, and corrosion-resistant materials, which serve to protect the inner layer and reinforce it. The outer layer should be able to effectively resist corrosive substances such as gravel and chemicals in the coal mining operation environment.

3、 Application of hydraulic hoses for coal mine supports

In the process of coal mining, hydraulic supports are important equipment that support the underground space of coal mines and provide a safe working environment for miners. Hydraulic hoses play a crucial role in supports, as they are responsible for transmitting hydraulic oil, controlling the lifting and lowering of supports, and providing strong support for coal mining.

1. Model and selection of hydraulic hoses

When selecting hydraulic hoses for coal mine supports, enterprises need to refer to the equipment's usage requirements and environmental characteristics to choose suitable products. Specifically, there are slight differences in pressure resistance, temperature, and functionality among different models of hydraulic hoses, and a reasonable selection should be made based on the actual situation. For example, for extremely low or high temperature environments, specially designed hydraulic hoses should be selected to ensure that they can maintain good performance even under extreme conditions.

2. Maintenance and upkeep of hydraulic hoses

The maintenance and upkeep of hydraulic hoses are key to ensuring their long-term stable use. Here are some effective maintenance methods:

-Regular inspection: Regularly inspect hydraulic hoses to ensure that there is no external mechanical damage or internal leakage.

-Cleaning dirt and dust: Keep the surface of hydraulic hoses clean to prevent dust and impurities from entering the system and affecting the quality of hydraulic oil.

-Check the connections: Ensure that all connections of the hydraulic hose are tight and leak free to avoid accidents caused by improper connections.

-Appropriate operating pressure: During use, avoid exceeding the rated pressure of the hydraulic hose to prevent it from bursting or other accidents.

4、 Market prospects of MSHA certified hydraulic hoses

With the continuous improvement of safety and technical requirements in the coal mining industry, the demand for MSHA certified hydraulic hoses continues to rise. Not limited to coal mines, with the expansion of underground engineering and other fields, the market prospects for such hydraulic hoses are becoming increasingly broad.

1. Policy promotion

The national emphasis on coal mine safety production and the continuous introduction of relevant policies have promoted the popularization of MSHA certified hydraulic hoses. According to industry standards, using MSHA certified products can significantly reduce safety hazards in coal mining operations, thereby reducing the incidence of safety accidents.

2. Technological progress

With the advancement of materials science and hydraulic technology, the performance of MSHA certified hydraulic hoses continues to be upgraded. For example, in the future, there may be hydraulic hoses that are lighter, stronger, and more heat-resistant, greatly improving the safety and efficiency of coal mining operations.

3. International market

In addition to the domestic market, MSHA certified hydraulic hoses can also occupy a place in the international market. Many countries and regions are strengthening the safety control of mining equipment, and certified products can meet the increasingly strict product compliance requirements in the international market.

Conclusion

In summary, the application of MSHA certified hydraulic hoses in coal mine supports and other equipment has played a crucial role. Its safety, durability, and efficiency are not only the guarantee for the smooth operation of coal mining, but also an important link related to the safety of miners' lives. With the development of the industry and technological progress, MSHA certified hydraulic hoses will play a more important role in the future market, contributing more safety guarantees to the sustainable development of the coal mining industry.