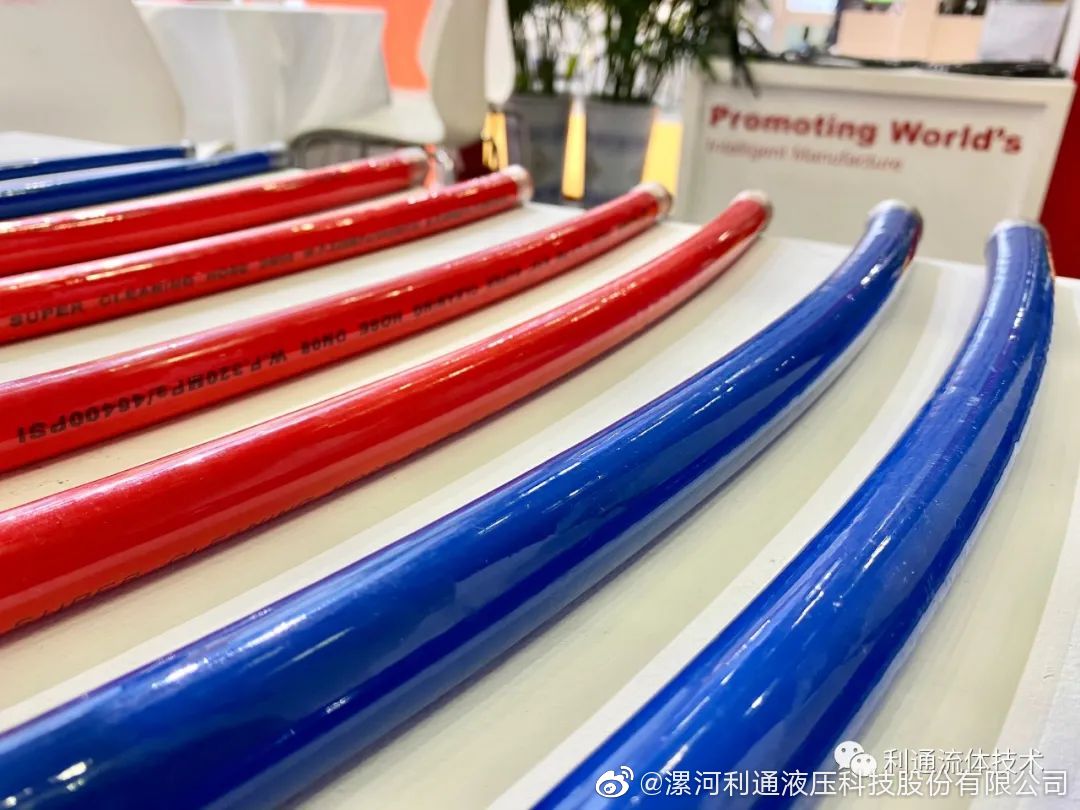

Maintenance techniques for high-pressure oil pipes and 4SH hoses

The use of high-pressure oil pipes and 4SH hoses is becoming increasingly common in modern industrial production and equipment maintenance. Whether it is automobiles, construction machinery, or hydraulic equipment, the stability and durability of oil pipes directly affect the efficiency and safety of the equipment. This article will comprehensively analyze the characteristics, selection criteria, application areas, and maintenance techniques of 30MPa high-pressure oil pipes and 4SH hoses, helping you better understand these two important hoses.

1、 Characteristics of 30MPa high-pressure oil pipe

A 30MPa high-pressure oil pipe is a specialized hose designed to withstand high-pressure fluids, typically made of multiple layers of high-quality polyurethane, rubber, or synthetic materials. Its features include:

1. Strong pressure resistance: As the name suggests, this high-pressure oil pipe is designed to withstand pressures up to 30MPa and is suitable for various occasions that require high-pressure transportation.

2. Temperature resistance: High pressure oil pipes can usually operate normally within the temperature range of -40 ℃ to 100 ℃, and some high-quality products can even reach higher temperatures. In addition, their high temperature resistance makes them suitable for some special industrial environments.

3. Wear resistance: The lining material of high-pressure oil pipes often has excellent wear resistance and can withstand multiple frictions without being easily damaged.

4. Good flexibility: The design ensures sufficient flexibility, making it easy to operate and install in small spaces.

5. Chemical resistance: Most high-pressure oil pipes can resist the erosion of various chemicals, ensuring safe use in industries such as petroleum and chemical.

2、 Characteristics of 4SH hose

4SH hose is a type of hose designed specifically for high-pressure hydraulic systems, typically consisting of four layers, providing excellent pressure resistance and service life. Its main characteristics include:

1. Four layer structure: 4SH hoses are usually composed of four layers of materials, including an inner lining layer, a reinforcement layer, and an outer layer. This design ensures safety in high-pressure environments.

2. High tensile strength: Due to the use of high-strength materials, 4SH hoses can still ensure excellent tensile performance under pressure.

3. Wide adaptability: 4SH hoses are not only suitable for high-pressure fluid transportation, but also for gas transportation, widely used in industries such as mining, metallurgy, and construction.

4. Temperature adaptability: Most 4SH hoses can operate normally in environments ranging from -40 ℃ to 100 ℃.

5. Aging resistance: High quality materials and structural design enable 4SH hoses to maintain their performance even after long-term use, making them less prone to aging.

3、 Standards for selecting high-pressure oil pipes and 4SH hoses

When selecting suitable high-pressure oil pipes and 4SH hoses, the following criteria should be considered first:

1. Pressure bearing capacity: Based on your specific usage environment, confirm the required upper pressure limit and choose the appropriate hose. Both 30MPa high-pressure oil pipe and 4SH hose can meet the high-pressure requirements, but it is necessary to ensure that they meet the actual requirements.

2. Inner diameter and length: Choose the appropriate inner diameter and length according to the fluid transport requirements to ensure stable flow rate and velocity.

3. Temperature resistance: Considering the temperature range of the working environment, choose oil pipes that can work safely at that temperature.

4. Chemical resistance: Select the appropriate material according to the type of transport fluid (oil, water, chemical liquid, etc.) to ensure that the hose is not corroded during use.

5. Certification standards: Select products that comply with industry standards (such as ISO, SAE, etc.) to ensure quality and safety.

4、 Application areas of high-pressure oil pipes and 4SH hoses

These two types of hoses play important roles in multiple industries, with specific applications including:

1. Automotive industry: High pressure fuel pipes are commonly used in fuel systems to ensure smooth delivery of fuel or other liquids; 4SH hoses are commonly used in hydraulic braking systems and power steering systems.

2. Construction machinery: The hydraulic system of construction machinery such as excavators and cranes requires the support of high-pressure oil pipes and 4SH hoses to ensure strong power of the equipment.

3. Mining and Metallurgy: In the mining and metallurgical industry, facing extreme working conditions, wear-resistant high-pressure oil pipes and 4SH hoses can effectively improve the service life of equipment.

4. Agricultural machinery: Modern agricultural equipment such as tractors and sprayers also use high-pressure oil pipes to ensure smooth operation.

5. Chemical industry: In situations where high-pressure transportation of chemical liquids is required, corrosion-resistant hoses are particularly important.

5、 Maintenance techniques for high-pressure oil pipes and 4SH hoses

Reasonable maintenance is crucial to ensure the long-term use of high-pressure oil pipes and 4SH hoses

1. Regular inspection: Regularly inspect the appearance of the hose, observe for cracks, wear, or deformation, and replace damaged parts in a timely manner.

2. Cleaning and maintenance: Regularly clean the inside of the hose with clean water or a suitable solvent to avoid the deposition of dirt and impurities that may cause poor fluid transportation.

3. Prevent excessive bending: During installation and use, try to avoid excessive bending of the hose and use appropriate elbows to reduce pressure on the hose.

4. Correct connection: Ensure that the connectors and joints connected to other devices are firm and reliable, avoiding oil leakage or damage caused by looseness.

5. Storage method: When not in use, store the hose in a dry and cool place, avoiding direct sunlight and high temperature environments.

Conclusion

High pressure oil pipes and 4SH hoses are undoubtedly indispensable and important components in modern industrial production. Understanding their characteristics, selection criteria, application areas, and maintenance techniques can help you manage and use these hoses more effectively, thereby improving the efficiency and safety of the equipment. Choosing appropriate oil pipes and hoses can not only improve work efficiency, but also effectively extend the service life of equipment. I hope that through the in-depth interpretation of this article, you can make wiser choices in practical applications.